Our services

Over 70 years of experience in the ZAMA industry

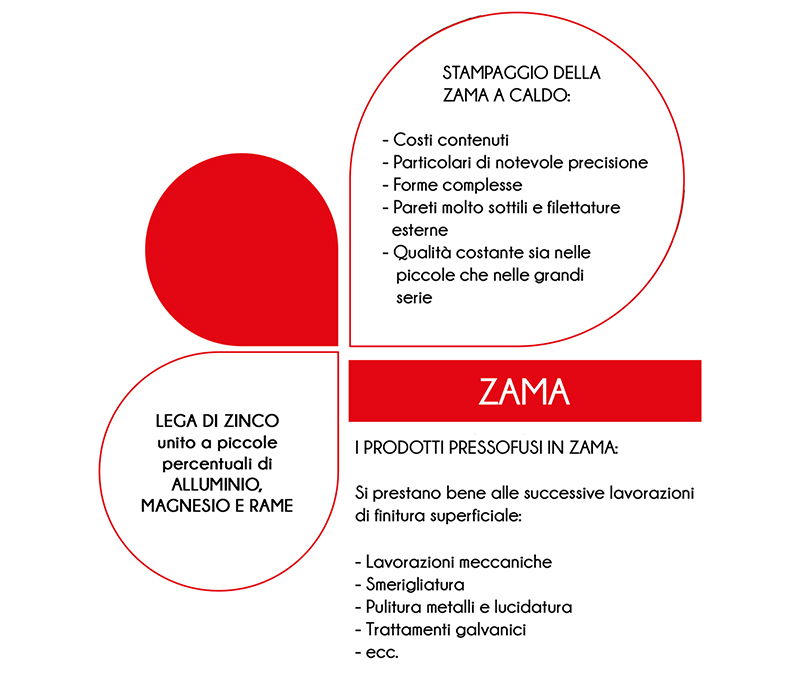

The ZINC ALLOY DIE CASTING is the manufacturing technique generally adopted for the production of products that require elegance, solidity, durability< /strong>, excellent respect for surfaces, galvanized surface finishes and above all very low dimensional tolerances for large and very large series with low production costs

In Italy

The quality is achieved using a statistical process of control according to AQL level 2 or 3

In China

Each production phase is followed by a 100% control phase of the pieces

Mechanical processing

Latest generation transfer machines used by trained technicians guarantee processing performed in the required tolerances

Cleaning

Completely automatic, where the most modern 14-head rotary tables of which the last one is robotic, have replaced the islands with anthropomorphic robots to be able to guarantee perfect productions

Galvanic

Completely automatic plant with 78 arms and built according to one of our patents, it is able to make a chrome plating in line with what is required by the strictest ISO standards and where trained technicians carry out every day all the tests needed to guarantee the constant quality of the finished product

Warehouse

Arranged to have a stock that allows us to be able to guarantee timely deliveries

Faucets

We produce zamak components for taps

Thermohydraulics

We produce finished articles for the hydro-thermo-sanitary sector

Ironware

We produce various items for the hardware store: handles, etc..

Technical articles

We can supply technical articles, such as: gas regulators for LPG cylinders.

Household

We can supply household items such as: Nutcrackers – Bottle openers

Industrial applications

We produce custom components for all industrial sectors.